Corrosive Powder

Corrosives Powder attack and chemically destroy exposed surfaces metal. They begin to cause damage as soon as they touch the skin, eyes, respiratory tract, digestive tract, or the metal. They might be hazardous in other ways too, depending on the corrosive material.Mostly corrosive powders are either acids or bases. Common acids include hydrochloric acid, sulfuric acid, nitric acid, chromic acid, acetic acid and hydrofluoric acid. Common bases are ammonium hydroxide, potassium hydroxide (caustic potash) and sodium hydroxide (caustic soda).Since, it corrodes the surface when exposed for longer duration, the contact surface should be Hastelloy / PTFE / PFE / EPDM coating or lined of required thickness. This will ensure the surfaces to be intact for longer duration.

Basic Information

| SL No. | Description | Remarks |

|---|---|---|

| 1 | Material to be conveyed | Chlorine |

| 2 | Material Form | Dry Powder |

| 3 | Conveying / Filling rate (Tons/Hr) | 2000Kg / Hr |

| 4 | Feed from | ANFD |

| 5 | Number of feed points | One |

| 6 | MOC | Contact Part: SS316 + PTFE Line ; Non Contact Part: SS304 |

| 7 | Area Classification | FLP ZONE-2 IIA,IIB. |

| 8 | Type of system preferred | Closed Loop |

| 9 | Conveying Distances in meters | 15 meters |

Material Properties

| SL No. | Important Parameters | Value |

|---|---|---|

| 1 | Bulk density (gm/cm³) | 0.5 |

| 2 | Angle of repose (°). | Not Available |

| 3 | Moisture content (%) | 0.50% |

| 4 | Temperature (°C) | Atmospheric (35°C) |

| 5 | Kindly specify max temp. product can withstand during conveying | 60 to 65C |

| 6 | Abrasive | Yes |

| 7 | Corrosive | Yes |

| 8 | Deliquescent | No |

| 9 | Explosive | No |

| 10 | Fragile | No |

| 11 | Free flowing | Yes |

| 12 | Hygroscopic | Yes |

| 13 | Coagulations | No |

Project Statement

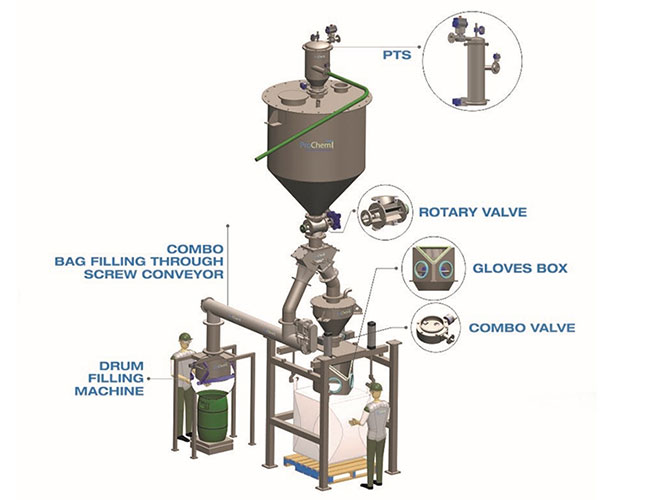

The output of ANFD has to be finally filled in 500Kg FIBC bags and 200L Drums. Based on the marketing requirement the type of filling changes. The process requirement is to completely empty the ANFD and should be ready for next batch for drying process. The ANFD capacity is 4KL and cycle time 4hrs-5hrs. The ANFD is on the 2nd floor. The dust generated during charging and filling were connected to client's dust collection system.

Project Detail

Jumbo bag has to put on bag unloading system by using hoist, first of all jumbo bag mouth to be clamp with unloading system and start system for the conveying process.

Vacuum blower/pump (pressure- 500mm/hg & flow 400 m3/h) started, at the same time massaging arms will be active for easy flow of material from the bag.

Material will be discharge from silo to Mixer with in control flow by using rotary airlock valve. At other condition if material filled 80 % of full volume, conveying system will be stop by using interlock of level sensor. Entire system operation is control by the PLC and HMI along with all instrument interlocks Like (sensors, proxy SW, PV, transducer) based on Automatic operation, only one operator will be handling entire process and operation activity.

RESULTS

Filling Rate

2000Kg/Hr

Manpower Required

1 or 2

Accuracy Filling

± 100gm

Noise Level

30Db

LATEST NEWS

Upcoming Events

Propak Asia 2024

Propak Asia 2024